KCKL GROUP FOR READYMADE GARMENTS INDUSTRY

We use the latest state of art technology for washes, designs, embroideries, patchwork, etc which are fully compliant to all international production, quality, and evaluation standards.

The company is seeking to apply an environmental management system, committing to related aspects with internationally recognized certifications system, decrease the emissions and pollution in water and air preserving resources to uphold the priority that the company gives to health, safety and the environment.

20 Years of Experience

Expert Team

The framework and method depends on expert team.

Target Fulfil

The framework and method depends on expert team.

Productivity

The framework and method depends on expert team.

Denim manufacturing services may include various stages

The industry has evolved over time, with sustainable practices and innovations playing an increasingly important role in modern denim production.

K .C . K . L Manufacturing

Product Development

Sustainability

We understand why sustainability is important for the environment and for the future generation. Therefore, we have taken steps to preserve our energy, gas, chemicals and water. Here are some of the implemented changes that we have made:

- We Installed new G2 waterless washing machine (Ozone machine) that saves water, energy and gas

- Replacing the light bulbs with LED light bulb technology, which saves 64% of electricity compared to the old bulbs

- We Have all steam lines insulated to save gas consumption

- We are Using water aerator in toilets to save water consumption

- We hold Monthly meeting with the staff to educate the employees for the importance of sustainability

- Turning computers into sleep mode after 15 minutes of non-usage to reduce electricity consumption

Pattern Making , Grading and Markers.

Pattern Fabrics

Pattern Grading

Marker plotter

Sewing and Cutting Department

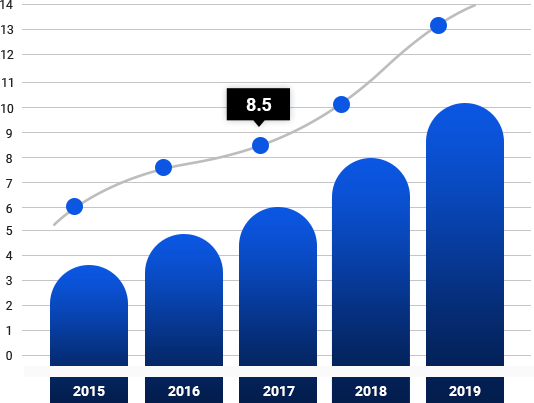

Completed

Projects

Satisfied

Clients

Team

Members

National Awards

Winner

We draw on our global network to assemble with the skills of task at hand.

Our Certificates

We are very happy to share client’s review.

Maria Silverii

Rabier Suab

Maria Silverii